Sustainability

a serious commitment, not a slogan

For some years now, CUF Milano and Centrufficio S.p.A. have been engaged in a process of limiting the effects that their production can have on the environment.

Production

Thanks also to the achievement of the environmental certification UNI EN ISO 14001, in this area are collected all the structural interventions related to headquarters, transport and machinery, such as:

- Installation of photovoltaic panels at the warehouses in Cologno, Pioltello, Modena and Vicenza as well as the branches in Brescia, Modena and Vicenza;

- Installation of electric car refuelling points at Pioltello headquarters and purchase of the first electric cars, which will gradually replace the entire fleet of around 60 vehicles;

- Promotion among its employees of the use of green vehicles, first and foremost bicycles, for which there is a special parking lot and bicycles available;

- Creation of a green area at the new headquarters in Pioltello of approximately 2,000 square meters, of which 200 square meters are used as a vegetable garden, cared for by the employees themselves, who have the right to harvest the vegetables for their own use and consumption;

- Use of low-consumption LED lights in all offices, as well as double or triple-glazed windows with low thermal transmittance profiles for energy savings in both summer and winter;

- Promotion of minimum use of paper and toner to all employees.

PRODUCT

The “product interventions” concern the raw materials and packaging used in the production of our products. Centrufficio S.p.A. was one of the first companies to comply with the Minimum Environmental Criteria, promoted by the Italian Ministry of the Environment, which include a series of requirements regarding the use of formaldehyde, volatile organic compounds and other potentially harmful substances.

Our melamine panels are CARB-certified, with very low formaldehyde emissions, and the coatings used are epoxy powder coatings that do not contain volatile organic compounds.

NO PLASTIC IS USED for the packaging, apart from a light film on the glass tops to prevent scratches and to hold together any high pallets: the corner pieces that repair all of our panels are made of cardboard, as are the packaging itself, from all of our own production lines.

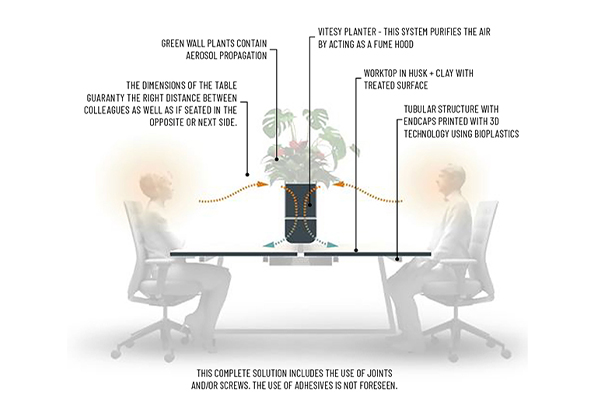

Our R&D team is developing, in collaboration with other realities transversal to the furniture sector, new materials and products in a perspective of CIRCULAR ECONOMY, for the reuse and recycling of waste itself. These products involve the recovery of two types of materials:

- Plastic materials, especially fiberglass (generally from the end of life of ship hulls or wind turbines), with the obtainment of a formaldehyde-free paste. The “Fibereuse” project, of which we are part, is carried out by the Polytechnic of Milan with financing from the European Community.

- Materials deriving from bio-building and organic waste from food production: thanks to the Hi-Hack / DesignTech program (for the realization of the coworking site inside the Mind area – ex Expo 2015) we are developing panels and furniture using these organic products, for the realization of totally sustainable offices.

All our vehicles are Euro 5 or Euro 6. Furthermore, we have started a process to replace our cars (currently already running on LPG) with electric cars.

Our logistics consists of many small territorial hubs, so that we do not have to make too many trips, trying to save annual CO2 emissions (there is, in this regard, an annual savings plan).

The subcontractors or suppliers are almost all part of our district: the sustainability of the furniture is not only in the materials, but also in the “zero km” that we can offer compared to others.

In the realization of the products, a disassembly sheet is drawn up so that all the materials can be recycled at the end of the life cycle of the furniture.

In addition to the use of innovative materials, as explained above, and in addition to the ease of disassembly and therefore the recovery of raw materials, we have a special department “expo” which is responsible for recovering all components or entire furnishings that can be reused and reuse them or for short-term rentals or for donations to public benefit organizations, such as schools and hospitals or charities, such as non-profit associations.